Operation Management – Introduction | CMA Inter Syllabus

Table of contents

CMA Inter Blogs :

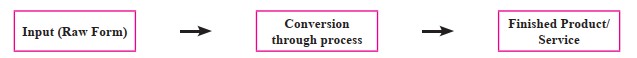

Operations Management (OM) encompasses all organizational activities that acquire the raw form of materials (input), process or convert into a consumable products and services as required to meet the needs of the end customers. OM deals with both tangible product and intangible services.

Example 1 (Product Centric)

Suppose, you require a smartphone. OM deals with procuring all raw materials such as chip, motherboard, battery, lens, speakers etc.; assemble and mount all components; test the performance of finished good; quality check; maintenance; storage and distribution for making the smartphone available to you.

Example 2 (Service Centric)

Suppose, you take a subscription of Netflix to watch a movie. OM covers all activities that includes dealing with movie-makers to get transmission right, make the movie available in the database, arranging for live streaming or recorded version transmission over spectrum and so on.

To better understand OM, let us have a simple diagram

Examples of input include, raw materials, machines, electricity, manpower, facilities, storage space etc.

In some cases, product and service are required both. For example, if you visit a retail shop. You not only require the availability of the products you want but also you expect courtesy of the salesperson, ambience, convenience of buying etc which are services. In fact, goods (tangible) and services (intangible) follow a trade off relationship over a continuum ranging from pure product (for example, study material) to pure service (for example, teaching).

Objectives of Operations Management

Objectives of operations management can be categorised into (i) Customer service and (ii) Resource utilisation.

(i) Customer service

The first objective is the customer service which means the service for the satisfaction of customer wants. Customer service is therefore a key objective of operations management.

The Operations Management must provide something to a specification which can satisfy the customer in terms of cost and timing. Thus, primary objective can be satisfied by providing the ‘right thing at the right price at the right time’.

These three aspects of customer service - specification, cost and timing - are described in a little more detail for the four functions in Table 1. They are the principal sources of customer satisfaction and must, therefore, be the principal dimension of the customer service objective for operation managers.

Table 1: Aspects of Customer Service

| Principal customer wants | ||

| Principal function | Primary consideration | Other consideration |

| Manufacture | Goods of a given, requested or acceptable specification |

Cost i.e. purchase price or cost of obtaining goods Timing, i.e. delivery delay from order or request to receipt of goods |

| Transport | Movement of a given, requested or acceptable specification |

Cost, i.e. cost of movement, Timing ,i.e. (i) duration or time to move (ii) wait, or delay from requesting to its commencement |

| Supply | Goods of a given, requested or acceptable specification |

Cost, that is purchase price or cost obtaining good Timing, i.e. delivery delay from order or request to supply, to receipt of goods |

| Service | Treatment of a given, requested or acceptable specification |

Cost, i.e. cost of treatment Timing, i.e. (i) Duration or timing required for treatment (ii) wait, or delay from requesting to its commencement |

Generally an organization will aim reliably and consistently to achieve certain standards, or levels, on these dimensions, and operations managers will be influential in attempting to achieve these standards.

Hence, this objective will influence the operations manager’s decisions to achieve the required customer service.

(ii) Resource Utilization

Another major objective is to utilize resources for the satisfaction of customer wants effectively, i.e., customer service must be provided with the achievement of effective operations through efficient use of resources. Inefficient use of resources or inadequate customer service leads to commercial failure of an operating system.

Operations management is concerned essentially with the utilization of resources, i.e., obtaining maximum effect from resources or minimizing their loss, under utilization or waste. The extent of the utilization of the resources’ potential might be expressed in terms of the proportion of available time used or occupied, space utilization, levels of activity, etc. Each measure indicates the extent to which the potential or capacity of such resources is utilized. This is referred as the objective of resource utilization.

Operations management is also concerned with the achievement of both satisfactory customer service and resource utilization. An improvement in one will often give rise to deterioration in the other. Often both cannot be maximized, and hence a satisfactory performance must be achieved on both objectives. All the activities of operations management must be tackled with these two objectives in mind, and many of the problems will be faced by operations managers because of this conflict. Hence, operations managers must attempt to balance these basic objectives.

Below Table 2 summarizes the twin objectives of operations management. The type of balance established both between and within these basic objectives will be influenced by market considerations, competitions, the strengths and weaknesses of the organization, etc. Hence, the operations managers should make a contribution when these objectives are set.

Table 2 : The twin objectives of operations management

| The customer service objective. | The resource utilization objective. |

| To provide agreed/adequate levels of customer service (and hence customer satisfaction) by providing goods or services with the right specification, at the right cost and at the right time. | To achieve adequate levels of resource utilization (or productivity) e.g., to achieve agreed levels of utilization of materials, machines and labour. |

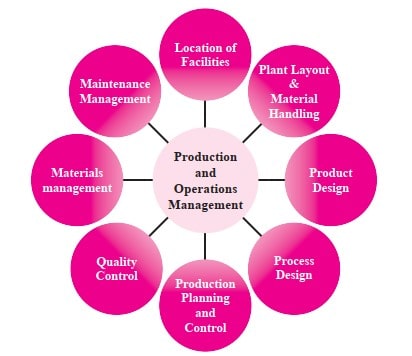

Scope of Operation Management

Operations Management concerns with the conversion of inputs into outputs, using physical resources, so as to provide the desired utilities to the customer while meeting the other organizational objectives of effectiveness, efficiency and adoptability. It distinguishes itself from other functions such as personnel, marketing, finance, etc. by its primary concern for ‘conversion by using physical resources’. Following are the activities, which are listed under Production and Operations Management functions:

The xyz Ltd requires to take few important decisions. The first question comes into picture is: “What to produce?”

This question is linked with the basic existence of the company It talks about the product that xyz Ltd. is manufacturing. Here, the organization needs to understand that what is the need of the customers in terms of product attributes/Features & quality. In other words, it talks about the competitive positioning of the company, its products acceptability at the market place this decision is based on the input received from market intelligence team and often is a part of the product design process later on we will study an important concept related to product design, such as QFD. In this regard, one important point to be noted that, many a times the organizations need to forecast about product life cycle & related requirement of the technology. Forecasting we will discuss separately.

One the company is aware that what it needs to produce, the second question comes: “How much to produce?”

This question is an ongoing questions, as the organization is engaged in estimating the quantity (“How much”) on a daily, weekly, monthly, quarterly & yearly basis. Again this information is obtained from marketing team. Based on the information received, the planning team (as a part of supply chain’s planning section) provides a forecast of demand. Hence, here deal with an important aspect of operational planning known as Demand Forecasting.

The next question is: “Where to produce?”.

This question leads to facility location selection problem after this, a series of questions need to be answered that lead to a member of decision areas such as “

Q: “How to produce?” (Process selection & Layout)

Q: “When to produce?” (Aggregate Planning inventory Master Production decision schedule)

Q: “Do we have materials to produce?” (MRP, Inventory Management) It also deals with Sourcing

Q: “Are we producing right things?” (Quality Management)

Q: “Are our machines able to provide desired results?” (Maintenance Management)

Q: “How to reach the products to the customers?”(Distribution or Delivery planning)

It includes transportation decision, warehousing, materials handling ets. Logistics issues In case the organization is practicing sustainability then another important decision area is reverse Logistics i.e., taking returns

Therefore, in summary the major decision areas are:

In Addition, an operations manager is also responsible for working capital management, skill-management etc.

The production management of today presents certain characteristics which make it look totally different from what it was during the past. Specifically, today’s production system is characterised by at least four features.

Modern Operations Management is characterized by the following :

Production Management vs Operations Management

There are two points of distinction between production management and operations management. First, the term production management is more used for a system where tangible goods are produced. Whereas, operations management is more frequently used where various inputs are transformed into intangible services. Viewed from this perspective, operations management will cover such service organisations as banks, airlines, utilities, pollution control agencies, super bazaars, educational institutions, libraries, consultancy firms and police departments, in addition, of course, to manufacturing enterprises. The second distinction relates to the evolution of the subject.

Operations management is the term that is used nowadays. Production management precedes operations management in the historical growth of the subject.

Recent trends in production and operations management relate to global competition and the impact it has on manufacturing firms. Some of the recent trends are :

Ruchika Ma'am has been a meritorious student throughout her student life. She is one of those who did not study from exam point of view or out of fear but because of the fact that she JUST LOVED STUDYING. When she says - love what you study, it has a deeper meaning.

She believes - "When you study, you get wise, you obtain knowledge. A knowledge that helps you in real life, in solving problems, finding opportunities. Implement what you study". She has a huge affinity for the Law Subject in particular and always encourages student to - "STUDY FROM THE BARE ACT, MAKE YOUR OWN INTERPRETATIONS". A rare practice that you will find in her video lectures as well.

She specializes in theory subjects - Law and Auditing.

Yash Sir (As students call him fondly) is not a teacher per se. He is a story teller who specializes in simplifying things, connecting the dots and building a story behind everything he teaches. A firm believer of Real Teaching, according to him - "Real Teaching is not teaching standard methods but giving the power to students to develop his own methods".

He cleared his CA Finals in May 2011 and has been into teaching since. He started teaching CA, CS, 11th, 12th, B.Com, M.Com students in an offline mode until 2016 when Konceptca was launched. One of the pioneers in Online Education, he believes in providing a learning experience which is NEAT, SMOOTH and AFFORDABLE.

He specializes in practical subjects – Accounting, Costing, Taxation, Financial Management. With over 12 years of teaching experience (Online as well as Offline), he SURELY KNOWS IT ALL.